Split laminate chair in oak

Two strips of oak rise from the rear, entwine, and return back to where they started. The chair is laminated in tension - glued laminates strapped and clamped around a curve - so only a ‘male’ former is required. This process was tested at fifth scale, and the ergonmic curves of the seat and back rest simulated with a full sized cardboard mock-up. A full sized prototype was made, using white oak (oiled to finish) and steel for the support (acid bathed and lacquered). The chair is available for sale - please contact us for more information.

Lounge chair

The lounge chair was an experiment into the processes involved with laminate plywood bending. The body of the chair is made from three positive curves biscuit jointed together. For each curve a male former was produced, laminates of plywood glued and tacked, and placed into a vacuum bag. Air was pumped out of the bag, and the laminates held to the curves as the glue went off. The armrests were made of oak veneer, using a male and female former. A structural stainless steel bar fixes the back of each armrest to each other, and prevents vertical movement of the body. The chair was sanded and waxed to finish. The prototype of the chair was manufactured in 2005.

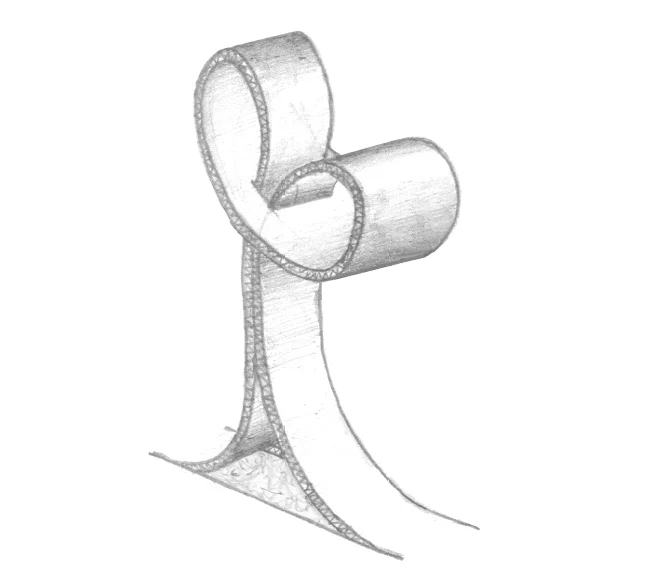

Peel and fold furniture

Permanent furniture that appears to have been peeled from the floor / walls and folded around itself. Seats and tables will be constructed using laminate wood bending. Each unit is bolted to the floor, allowing for the layout to be reconfigured. Voids are exposed under the peeled body of the chairs, some of which will be left to give a negative imprint of the chair's profile. A variety of materials and finishes can also be used in the voids (concrete and grass) playing upon the materiality of indoor and outdoor space. A fifth scale model was made, and a full sized prototype will be produced.